RyderShip™ is the ultimate e-commerce fulfillment software built by Ryder and designed to integrate smoothly with your existing e-commerce technology. It streamlines the process of turning orders into shipped packages. RyderShip™ serves as a centralized command center, offering control over various aspects of your business operations. This includes order management, inventory tracking, order status tracking, returns management, and more, allowing you to efficiently oversee and manage multiple aspects of your business within a single platform.

Logistics

Warehousing & Fulfillment

Transportation

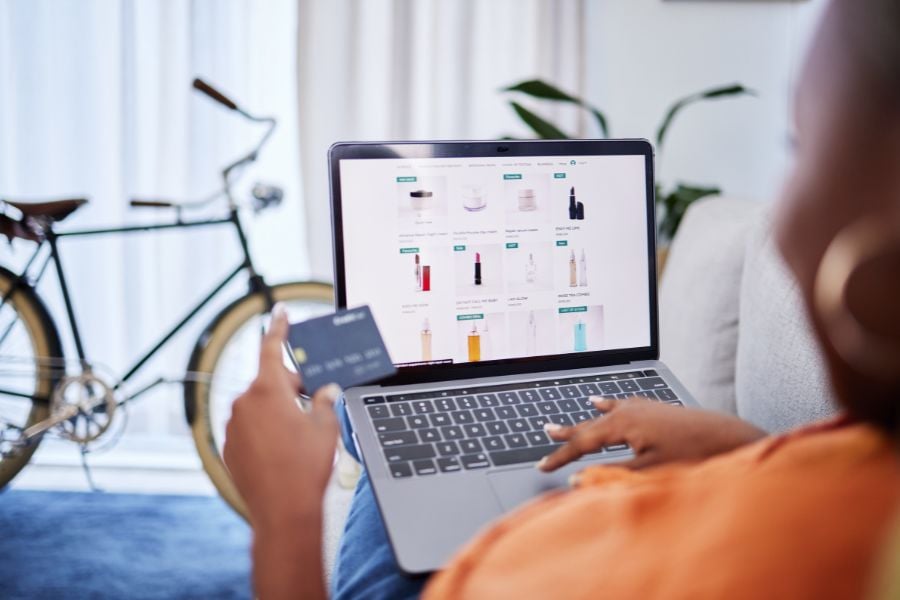

E-commerce

E-commerce Fulfillment Services

Lease & Maintenance

Semi Trucks

Supply Chain Technology

Logistics

E-commerce

Lease & Maintenance

Buy Used Trucks