Logistics

Warehousing & Fulfillment

Transportation

E-commerce

E-commerce Fulfillment Services

Lease & Maintenance

Semi Trucks

Supply Chain Technology

Logistics

E-commerce

Lease & Maintenance

Buy Used Trucks

It’s easy to think of preordering as a faux pas in the age of always-on retail. After all, why would a customer want to pay upfront and wait for an item if they can find something similar elsewhere?

There are two key reasons why many consumers are happy to place preorders in 2022. Firstly, they prefer to do business with retailers they know and trust. Secondly, supply chain disruptions caused by the pandemic have sometimes made preordering a necessity for consumers.

With consumers having grown accustomed to longer wait times since 2020, merchants who have the ability to process and handle preorders effectively have a huge competitive advantage.

However, taking preorders isn’t without risk. When executed well, preorders aid customer retention and build higher levels of brand loyalty. But late delivery, poor communication, or canceled preorders can seriously damage your brand’s reputation.

If you’re planning on introducing a preordering system, you need to be certain that you have the ability to deliver (no pun intended).

In this article, we’re going to weigh up the pros and cons of preordering and the prerequisites for handling preorders effectively—with some help from our friends at ChannelApe!

Preordering is an inventory management strategy where customers can place orders for items that don't have sufficient stock at the time of purchase.

When an item is preordered, that customer will be first in line for additional stock once it arrives from the supplier or manufacturer. This may take several days or weeks, depending on product availability.

Preordered items are a clear sign that customer demand exceeds supply for certain SKUs or collections. Accepting preorders helps retailers to avoid missing out on valuable sales and keep pace with purchasing trends, while also offering good customer service.

However, managing preorders does require adding new workflows to your fulfillment process. Brands need to be certain that they are capable of robust preorder fulfillment and monitoring—or else they could end up letting down customers.

Preordered items differ from out-of-stock products in that retailers can guarantee delivery within a reasonable timeframe, either due to ongoing shipments of that SKU or a strong relationship with the supplier that enables a 'just in time' approach to inventory management.

When a SKU is out of stock, this is usually because the inventory is seasonal and/or the retailer cannot get more stock from the supplier. In either of these cases, brands shouldn't be accepting preorders because they can't give an accurate delivery time frame.

Even with robust demand forecasting, it can be difficult to know how well a new product is going to perform with customers. There's a very fine line between being conservative with inventory levels to avoid excess inventory and dead stock, or ordering extra units to avoid missing out on potential sales.

If a brand has a good relationship with their supplier, they may decide to order less inventory with the intention to accept preorders to meet demand if the product proves popular. This ensures that their next shipment of inventory is guaranteed to sell quickly and keep customers happy, rather than taking up valuable storage space that could be occupied by faster-moving SKUs.

There are a variety of external events which can either dampen—or heighten—demand for different SKUs that historical data cannot predict. For example, if one of your products is featured on a blog or plugged by a popular influencer, your normal inventory levels may not be enough to meet the sharp increase in demand. Likewise, unseasonal weather conditions or new pop culture trends may force brands to add preorders to the order fulfillment process for certain products, especially if they have low safety stock.

Preordering has become a much more common practice during the COVID-19 pandemic, thanks to the factory closures and shipping slowdowns caused by lockdowns and labor shortages. To avoid losing customers to competitors during a time of uncertainty, brands have relied on preordering to 'lock in' a sales order to honor fulfillment and delivery at a later date. For customers, this gives them reassurance that they will eventually receive the preordered item, rather than having to search around and find another vendor.

Some retailers may end up under pressure to accept preorders if they end up accidentally taking customer orders for items that are out of stock. This can happen when merchants experience issues with the integration between their ecommerce platform and inventory management system, meaning SKUs might not show up on the website as out-of-stock items. Because the brand has already processed payment for the sale, it may be preferable for them to offer the customer a preorder first rather than a refund.

Humans are social animals, meaning we’re constantly looking for social proof for what products we should buy. A whopping 97% of consumers say that customer reviews influence their purchasing decisions. When an item is experiencing its highest demand, either constantly sold out or on the verge of selling out, it's a sign that it's a good purchase.

Scarcity is a marketing and inventory management tactic where brands deliberately stock only a small amount of a product to drive demand. Scarcity works because it leverages a very primal consumer instinct; the harder something is to access, the bigger a status symbol it becomes. In sum, preordered products often become even more desirable to customers—simply by virtue of being on preorder.

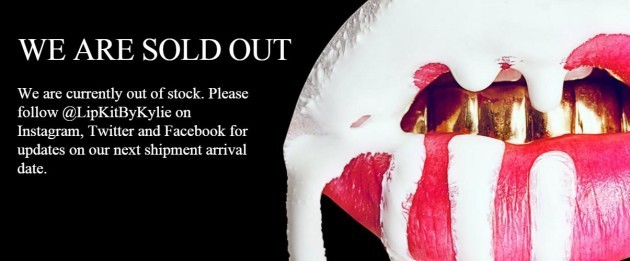

Kylie Cosmetics is a great example of a brand that has used scarcity to increase brand awareness in the highly competitive cosmetics market. Their inaugural Lip Kits sold out just minutes after they first went live in 2015, with products later being listed on eBay for thousands of dollars.

By closely controlling stock levels, Kylie Cosmetics was able to shape the desirability of the brand and build demand.

Brands can take this a step further by preordering products that are artificially scarce. This enables you to leverage consumers’ Fear of Missing Out (FOMO) by persuading them to pay upfront to guarantee their spot in your next shipment. In sum, preordering is a very useful tactic to fuel demand and increase the perceived value of your product.

While preordering helps to cut down holding costs by reducing the amount of outstanding storage space you need to maintain, it can substantially increase your overall fulfillment costs. Managing more orders means more administrative time spent processing, updating, and fulfilling them, in addition to an increased volume of customer service requests. All of this takes valuable time away from managing your business’s growth.

Preorders also complicate the fulfillment process in cases where a customer is buying additional items that are currently in stock. After all, it isn't reasonable to expect customers to wait for the preordered product to arrive before they receive the rest of their order. Split shipments—with their associated packaging, shipping, and handling costs—can significantly cut your profit margins.

If an item at your online store is sold out, consumers will immediately begin looking for alternatives at other retailers. In sum, every sold-out item represents a lost opportunity for a consumer to establish a lasting relationship with your brand.

A preordering system enables you to strike while the iron is hot and hook in shoppers while their need is there—rather than running email campaigns designed to hook customers in once a product is back on the shelf. By the time this happens, it’s often too late to secure a sale. Customers have either fulfilled their needs elsewhere, or they’re no longer interested. This kind of messaging can make your brand look unable to keep pace with your customer’s needs.

If your brand has a well-established customer base, many customers may prefer the certainty of shopping with a retailer they know—even if it means a delay in receiving the product—rather than taking a chance on an unknown vendor. In sum, preordering presents a valuable opportunity to build brand trust and affirm customers’ faith in you.

Delivery anxiety is a widespread issue in ecommerce due to the lack of transparency during the fulfillment and shipping process. This is even more pronounced for preordering, thanks to the long lead times between purchasing and receiving the order.

Today’s consumers expect a high level of contact with brand representatives, and they’re not going to hang around if they don’t receive it. According to Zendesk, around 80% of consumers say they would rather do business with a competitor after just one bad experience.

When a customer places a preorder, they expect regular updates from the brand about its progress and estimated delivery time. The more preordered items you have on record, the more your support team's bandwidth will be taken up by the need to continually inform customers about their preorder status.

If your business is going to implement a preordering system, you need to be certain that your customer care team is able to handle a consistently high volume of service requests. If there’s going to be a long lead time for certain products, that equals a lot of ‘where is my order’? requests. This is why it's also essential to have an efficient inventory management system so your team can retrieve preorder status information quickly and minimize delays.

Predicting demand for different SKUs can be a crystal ball gazing activity. Even with sales reports or market insights that span multiple years, there’s a whole host of external events that can either dampen or fuel interest in different products.

It’s common for merchants to place large orders to access bulk discounts and avoid missed sales opportunities. But if your sales forecast is wrong, this can leave your brand saddled with excess inventory—leading to higher holding costs and lower profit margins due to the need for steep discounting.

With a preordering system, your brand knows exactly how many units are needed for your next shipment. This helps to take the guesswork out of inventory management and keep excess inventory to a minimum.

While you may have enticed someone to place a preorder, this doesn't mean that it's a completed sale. There’s nothing to stop that customer from canceling their preorder because they’ve grown tired of waiting, or because they’ve found an alternative vendor.

This is the risk that comes with accepting too many preorders for a product; it's possible that you may end up ordering more units than you have outstanding preorders for, resulting in a squeeze on storage space.

While you can minimize the risk of this happening with proactive communication and only offering refunds up to the date that your next shipment is dispatched, it’s impossible to prevent canceled orders altogether. Hassle-free return and refund policies have become the norm, and some consumers are highly unlikely to place a preorder unless they have the right to cancel at any time. It's also worth bearing in mind that the longer the lead time, the more likely it is that your customers will grow impatient and start looking elsewhere.

Now we arrive at the golden question: Is preordering a good idea?

The answer is yes: If you have the infrastructure and workflows to manage preorders effectively.

Regardless of whether preordering is unintended or part of a deliberate strategy to fuel demand among your customer base, retailers should know how to meet consumer expectations for a seamless preordering experience. If your brand cannot fulfill preorders effectively, this could do serious damage to your brand's reputation.

Multi-brand retailers know that not all supplier relationships are alike. While there are some suppliers where you can pick up the phone and request more stock at short notice, this won't be the case across the board. In some cases, it can take several weeks for order requests to be approved, let alone shipped. This has been a particular problem during the pandemic, where supply chain challenges have seen inventory delayed by months due to shipping and manufacturing disruptions.

In sum, you need to be certain that a particular supplier is able to meet the deadline promised, or preordering is going to do a lot more harm than good. If a certain supplier cannot guarantee reasonable lead times, you shouldn’t offer preorders for those products.

At its heart, successful preordering is all about the inventory management process. When you’re accepting orders for products that you don’t currently have in stock, it takes extremely well-oiled workflows to ensure that preorders can be fulfilled efficiently and don't get lost within the depths of your system. At a minimum, you should have the following in place:

Managing preordering independently is a massive undertaking, even for established ecommerce brands. If you're currently practicing in-house fulfillment, adding this additional workflow into the mix can easily overwhelm a growing business.

This is why it's a good idea to seek outside expertise to ensure that your preordering strategy goes smoothly.

The Ryder and ChannelApe integration offer Ryder merchants the ideal capabilities for seamless preorder and inventory management. By connecting Ryder’s scalable fulfillment network with ChannelApe’s real-time inventory and order management capabilities, merchants gain access to an intuitive, all-in-one dashboard that gives them unparalleled visibility over their outstanding orders.

Thanks to ChannelApe's unique pre-selling tool, brands can begin selling products to customers that are in transit as part of a purchase order. This means you'll always know how many units you have available in the short term, opening the way for seamless preorder management.

With access to ChannelApe’s virtualized inventory and Ryder's nationwide network, brands can focus on sustainable, flexible growth while maintaining memorable customer experiences that drive revenue and retention.